- |

- English

- |

- Inquiry List

- |

- Sign In or Sign Up

1. Special chip-removing design, high effiiciency, save cost for customers.

2. Stress ring: through a number of reasonable rolling technology, so that the internal stress is evenly distributed, and the body stability is higher.

3. Using imported materials: Kenlar ripping saw blade has the advantages of hard alloy, high wear resistance, the overall stability, smooth cut, low noise.

Applicable: fine and precise cutting

Suitable for machinery: table saw

Applicable materials: ripping solid wood.

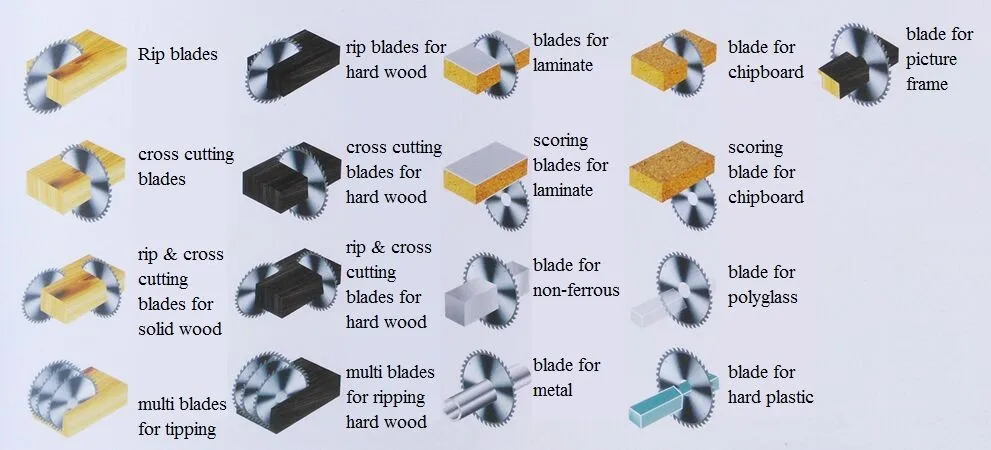

Please tell us the cutting material and cutting ways, we'd like to recommend you right product.

Specifications

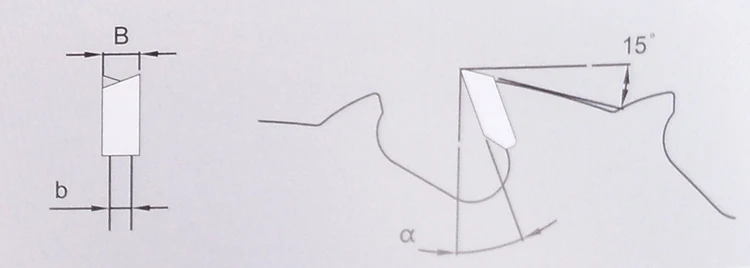

| Outer diameter | Kerf | Thickness | Bore | Teeth number | Cutting angle | Teeth type | Positioning hole |

| D (mm) | B (mm) | b (mm) | d (mm) | Z | a | T-type | |

| 230 | 3.2 | 2.2 | 25.4 | 40 | 15 | ZY | |

| 230 | 3.2 | 2.2 | 30 | 40 | 15 | ZY | FT01 |

| 230 | 3.2 | 2.2 | 30 | 40 | 15 | ZY | FT03 |

| 250 | 3.2 | 2.2 | 25.4 | 40 | 15 | ZY | |

| 250 | 3.2 | 2.2 | 30 | 40 | 15 | ZY | FT01 |

| 250 | 3.2 | 2.2 | 30 | 40 | 15 | ZY | FT03 |

| 250 | 3.2 | 2.2 | 25.4 | 60 | 15 | ZY | |

| 250 | 3.2 | 2.2 | 30 | 60 | 15 | ZY | FT01 |

| 250 | 3.2 | 2.2 | 30 | 60 | 15 | ZY | FT03 |

| 300 | 3.2 | 2.2 | 25.4 | 48 | 15 | ZY | |

| 300 | 3.2 | 2.2 | 30 | 48 | 15 | ZY | FT01 |

| 300 | 3.2 | 2.2 | 30 | 48 | 15 | ZY | FT03 |

| 350 | 3.5 | 2.5 | 25.4 | 54 | 15 | ZY | |

| 350 | 3.5 | 2.5 | 30 | 54 | 15 | ZY | FT01 |

| 350 | 3.5 | 2.5 | 30 | 54 | 15 | ZY | FT03 |

| 400 | 3.5 | 2.5 | 25.4 | 60 | 15 | ZY | |

| 400 | 3.5 | 2.5 | 30 | 60 | 15 | ZY | FT01 |

| 400 | 3.5 | 2.5 | 30 | 60 | 15 | ZY | FT03 |

* Teeth type.

Packing

1. protection ring covers teeth, enclosed in plastic bag.

2. Blank box or printed box.

3. Strong outer packing.

Production Flow

* Laser cut

* CNC brazing

* Flattening

* CNC grinding teeth

......

Warranty

1. Kenlar saw blade is strictly inspeced after each process for cutter body thickness, size, flatness, bore, angle, welding, hardness, etc. We promise to ship 100% qualified product.

2. The blade is made of alloy which is high hardness but brittle. We have blade cover to well protect the knives, in case the damage caused during transportation (the damages include broken knife, unstable knife, cracked body), please take pictures when you receive it, we'd like to replace for you or reduce this amount in next order.

3. These are not in after sales service: the blade is not sharp when required grinding, broken blade by improper use, blade off, problems by self revising hole, unsuitable use purpose.

FAQ

Q: Are you trading company or manufacturer?

A: We are 12 years factory, foreign sales team set up in 2014, the team manager has 13 years rick experience to tenderly take care of your orders.

Q: How long is your delivery time?

A: Usually we produce most regular size in stock, can ship as soon as possible. Otherwise, the producing time is 5~15 days.

Q: Do you provide free samples?

A: Yes, our pleasure. 1 pc for free, on your express cost. 2~10 pcs will charge 80% of formal quotation, and will advise most economical shipping way.

Q: What are your payment terms?

A: TT, L/C, Western union, paypal, Alibaba trade assurance or the way you like, we can discuss details.

Q: There are some wood cutter suppliers, why I choose you?

A: We are factory, over 13 years, professional in manufacturing finger joint cutter, TCT plane knife, drill bit and saw blade! In China, we are top 3 factory. Zhejiang, Guangzhou, Shanghai, Shenzhen, Hebei distributor & export company buy from us. We welcome foreign buyers directly.

Q: How to buy from you?

A: Send me inquiry and specify the specifications, usage, quantity, address ====> I will send you quotation (usually we quote you CIF, you can overall calculate your cost)====>We discuss payment terms, shipping ways ====> Send PI=====>You pay deposit or full payment====>Start produce or stock available====>ship====>after-sales====>welcome again.